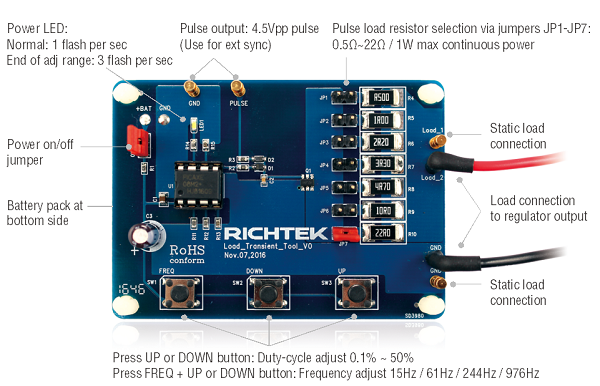

Figure 1: Richtek Load Transient Tool connections and

functions

The Richtek Load Transient Tool contains a micro controller

that switches a MOSFET on and off with a certain duty-cycle. When connected

to a voltage regulator output, the MOSFET switches a load resistor on and off,

thereby creating a fast changing pulse load. The tool can generate very fast

load steps (~500nsec rise/fall times), and can be applied to any voltage regulator

output in your system. My measuring the regulator output voltage during the

fast load step, the regulator control loop behaviour can be observed.

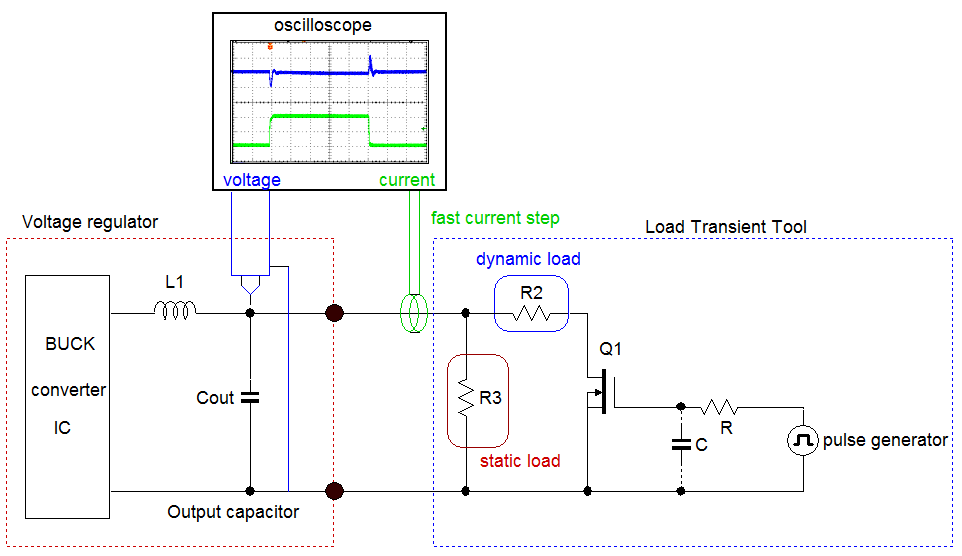

Figure 2: Basic Load Transient measurement method

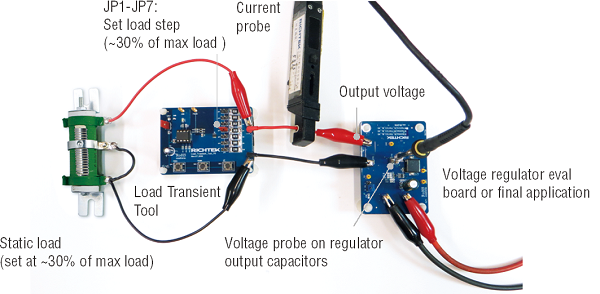

Figure 3: Practical Load Transient Tool measurement setup

A fast load step will excite the system control loop over

a wide frequency range. Control loop instability or under damped response can

be seen as output voltage ringing. This is only valid for CCM (continuous current

mode) operation, so PSM-CCM transitions should be avoided. Always adjust the

static load for CCM operation range during the load step.

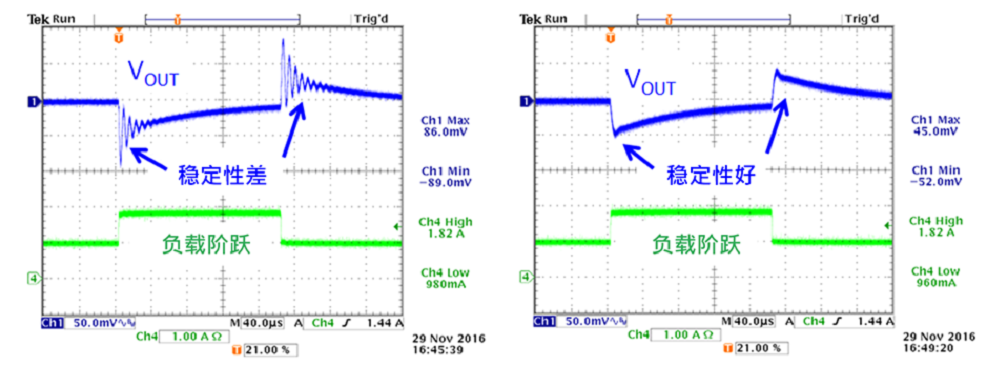

Figure 4 shows an example of a poor and a good load step

response of a 3.3V / 3A converter. The example on the left side shows that the

regulator output voltage has severe ringing after a load transient, indicating

that the control loop has marginal stability. In most cases this is related

to the converter feedback loop compensation in combination with the output capacitor

value.

Figure 4: example of poor and good load step response

Besides control loop stability issues, other resonance

effects due to layout parasitic trace inductance, input supply ringing etc.

can also be quickly identified with the fast load transient tool.

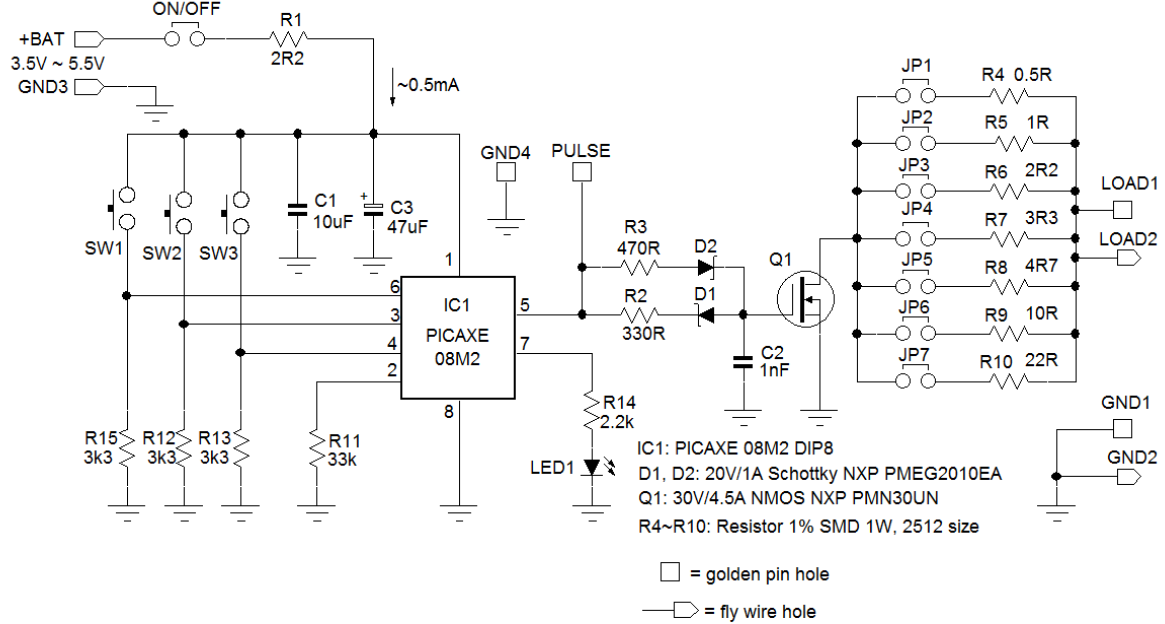

Figure 5: Load Transient Tool schematic

The schematic in figure 5 shows the the micro controller

which drives the MOSFET switch. The MOSFET gate drive is designed to generate

equal switching speeds with ~500nsec rise/fall times. Reducing or removing C2

can increase the switching speed, but the actual load current transient speed

will be mostly determined by the wiring inductance between the tool and the

application. Especially when testing low voltage supplies (< 2V), it may

be necessary to use short, thick wires between the tool and the application

to minimize inductance, see figure 6.

Figure 6: Reducing wire inductance between transient tool

and application for faster load step speed.

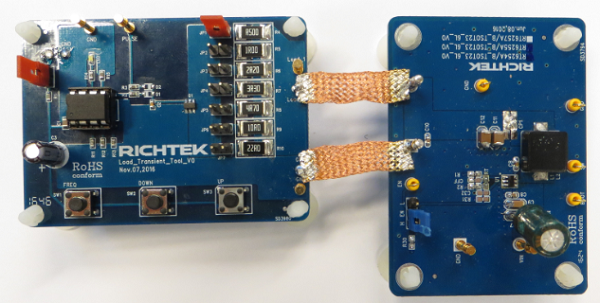

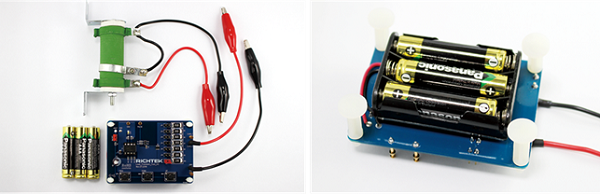

The tool consists of a load transient board, an adjustable

power resistor for setting static load and battery pack, see figure 7.

Figure 7: Richtek Fast Load Transient Tool kit.

Guidelines for use:

- Insert 3x1.5V AAA batteries in the battery holder. Please note the correct

polarity.

- Connect the power jumper: Power LED lights for 1 second, and then flashes

once per second. (Default start-up frequency is 244Hz with 5% pulse load

duty-cycle).

- Connect the Load_2 & GND connection to regulator output.

- Connect the adjustable 10Ω power resistor to the static load pins.

Adjust the slider for low level load current to be in CCM mode (or ~30%

of regulator max load).

- Insert the jumper to JP1~JP7 for desired pulse load resistor (suggestion for stability check: VOUT/RLOAD ≈ 30% of maximum converter load)

- Measure the pulse load current in the load wire and observe voltage

regulator output during load transient. Ringing in the voltage waveform

can point to insufficient stability.

- The PULSE output can be connected to scope ext sync. Note that doing

this can create ground loops and the regulator output voltage reading may

be affected.

- The pulse load duty-cycle can be adjusted by pressing UP and DOWN buttons.

The adjustment range is 0.1% ~ 50%. The power LED will flash quickly when

end of adjustment range is reached. Note that the power dissipation in the

pulse load resistors increases when duty-cycle is increased. Do not exceed

1W average power!

- The pulse load frequency can be changed by pressing FREQ + UP or DOWN

buttons together. The frequency adjustment range has 4 steps: 15Hz, 61Hz,

244Hz (default) and 976Hz. The power LED will flash quickly when end of

adjustment range is reached. Duty-cycle is maintained when changing frequency.

- 10. Remove the power jumper to stop the pulse load generator. Static

load will remain.

- Re-insert power jumper will reset pulse load duty-cycle to 5% and frequency

to 244Hz.

For more information on converter loop

stability and load transient testing, please read the application note AN038

“DC/DC

converter testing with Fast Load Transient”